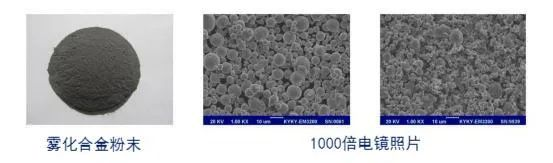

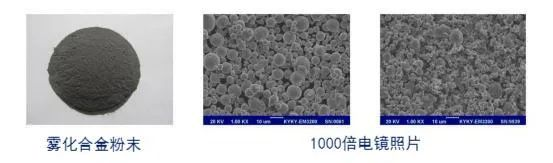

雾化合金粉末系列

发布日期:2020-04-15 13:57:02 浏览次数:

雾化合金粉是指用雾化法制得的金属粉末,即利用高压气流或水流、离心力等工艺,将一种或多种熔融金属液流粉碎成液滴,冷凝后得到的金属或合金粉末。根据雾化介质的不同,雾化法可以分为气雾化、水雾化、离心雾化等工艺。气雾化粉末球形度好,杂质含量低;水雾化粉末形貌属于不规则形状,含氧量高,粉末成型保型性好。公司雾化合金粉系列产品主要有雾化合金粉-316L、304L(奥氏体不锈钢合金粉)、雾化合金粉-17-4PH(马氏体不锈钢合金粉)、雾化合金粉-F75(钴铬钼高温合金粉)。

雾化粉末特性:

雾化粉末特性:

- 纯度高,杂质含量少;

- 粉末表面光滑;

- 烧结产品机械性能好.

1、水气联合雾化

| 牌号 |

成分 (Wt%) |

D50 |

| Cr |

Ni |

Mo |

Cu |

Mn |

Si |

C |

O |

Other |

| 316L |

16-18 |

10-14 |

2-3 |

|

≤2 |

≤1 |

≤0.03 |

≤0.4 |

|

8-13 |

| 17-4PH |

15.5-17.5 |

3-5 |

|

3-5 |

≤1 |

≤1 |

≤0.07 |

≤0.4 |

Nb:0.15-0.45 |

8-13 |

| 304L |

18-20 |

8-12 |

|

|

≤2 |

≤1 |

≤0.03 |

≤0.4 |

|

9-12 |

| 410 |

11.5-14.5 |

|

|

|

≤1 |

≤0.6 |

≤0.15 |

≤0.4 |

|

9-12 |

| 420 |

12-14 |

≤0.6 |

≤0.65 |

|

≤1 |

≤0.6 |

0.16-0.25 |

≤0.4 |

|

9-12 |

| 420-A |

12-14 |

≤0.6 |

≤0.65 |

|

≤1 |

≤0.6 |

0.5-0.7 |

≤0.4 |

Nb:1-2 |

9-12 |

| 2507 |

24-26 |

6-8 |

3-5 |

|

≤1.2 |

≤0.8 |

≤0.03 |

≤0.4 |

|

9-12 |

| 430 |

16-18 |

≤0.6 |

|

|

≤1 |

≤0.8 |

≤0.12 |

≤0.4 |

|

9-12 |

| 440C |

16-18 |

≤0.6 |

≤0.75 |

|

≤1 |

≤0.8 |

1.3-1.6 |

≤0.4 |

|

9-12 |

| Cr12MoV(SKD11) |

11-12.5 |

|

0.4-0.6 |

|

≤0.4 |

≤0.4 |

1.45- 1.7 |

≤0.4 |

|

9-12 |

| FeCo50 |

|

|

|

|

|

|

≤0.1 |

≤0.4 |

Co:48-52 |

9-12 |

| F75 |

26-30 |

|

5-7 |

|

|

|

≤0.2 |

≤0.1 |

|

9-12 |

| FeSiCr |

5-6 |

|

|

|

|

5-6 |

|

|

|

- |

| 8620 |

0.4-0.6 |

0.4-0.7 |

0.15-0.25 |

|

|

|

0.12-0.23 |

|

|

4-8 |

2、气雾化 MIM不锈钢系列

| 牌号 |

成分 (Wt%) |

D50 |

| Cr |

Ni |

Mo |

Cu |

Mn |

Si |

C |

O |

Other |

| Q316L |

16-18 |

10-14 |

2-3 |

|

≤2 |

≤1 |

≤0.03 |

≤0.15 |

|

12.0-15.0 |

| Q17-4PH |

15.5-17.5 |

3-5 |

|

3-5 |

≤1 |

≤1 |

≤0.07 |

≤0.15 |

Nb:0.15-0.45 |

11.0-14.0 |

| Q304L |

18-20 |

8-12 |

|

|

≤2 |

≤1 |

≤0.03 |

≤0.15 |

|

11-14 |

| Q420 |

12-14 |

≤0.6 |

≤0.65 |

|

≤1 |

≤0.6 |

0.16-0.25 |

- |

|

11-14 |

| QM2 |

3.8-4.4 |

≤0.3 |

4.5-5.5 |

≤0.25 |

0.15-0.4 |

0.2-0.45 |

0.8-0.9 |

- |

V:1.75-2.2

W:5.5-6.75 |

- |

QFeSi系列

| 产品 Products |

磁饱和感应强度Bmax |

磁损Core Loss |

居里温度Curie Temperature |

直流偏置DC-Bias |

| QFeSi |

16000Gs |

≤520mW/cm3@ue=60 |

700℃ |

≥75% @100 Oe |

| QFeSiAl |

10500Gs |

≤200mW/cm3@ue=60 |

600℃ |

≥60% @100 Oe |