YUEAN Advanced Materials’ Carbon Neutrality Commitment for Construction Ecosystem and Industry Development

Published Date:2023-10-16 11:14:22 Hits:

At the United Nations Climate Summit in 2020, China officially declared its “30•60”goal, peaking its carbon dioxide (CO2) emissions before 2030 and achieving net-zero emissions before 2060. On October 26, 2021, The State Council of China issued the "Action Plan for Achieving Carbon Peak before 2030" (the Plan). The Plan focuses on implementing the strategic decisions of the Party Central Committee and The State Council for“carbon peak & carbon neutrality”, aligning with efficient resource use, green growth, and environmentally friendly living patterns. Vigorous implementation of specific targets and tasks across regions and industries is paramount, integrating carbon reduction initiatives into the broader economic and social framework while guarding against risks.

On January 2023, at the first meeting of the 14th People's Congress of Jiangxi Province, the Construction of the National Ecological Civilization Pilot Zone Report (the Report) proposed to transform and upgrade of all industries, and promote carbon peak and neutrality effectively with prioritization... Vigorously implement the three-year action about the development zone’s photovoltaic construction.

To execute based on the instruction of the Plan and follow the spirit of the Report, JIANGXI YUEAN ADVANCED MATERIALS CO.,LTD. ("YUEAN Advanced Materials ") has implemented a carbon-neutral action plan since 2023, aligning with the national and provincial agenda of carbon peak and carbon neutrality.

Milestone 1: Distributed Photovoltaic Power Generation Project and BIPV Photovoltaic Power Generation Project

Photovoltaic technology is an essential means to support zero carbon in renewable energy generation using solar and wind power. According to the International Renewable Energy Agency, photovoltaic will become a major energy source. The two photovoltaic projects invested by YUEAN Advanced Materials has been fully implemented in 2023. The roof BIPV photovoltaic power generation adopts the self-generated surplus electricity on-grid rooftop power station. The annual power generation is 2,377,500 kWh, which can reduce carbon dioxide emissions by 2,595.99 tons per year, and save 854.05 tons of standard coal per year.

The roof BIPV photovoltaic power generation project, adopts the principle of "self-use and surplus electricity grid connection", and the consumption ratio reaches 90%. The annual power generation is 428,300 kWh, and the average annual utilization hours are 1,086h. It aims to reduce carbon dioxide emissions by 439.93 tons per year and save about 144.73 tons of standard coal per year.

The total annual power generation of the two photovoltaic projects is 2.8058 million kWh and aim to reduce carbon dioxide emissions by 3035.92 tons per year, equivalent to the reduction of 1241.4 acres of forest emissions, and save about 998.78 tons of standard coal per year.

The total annual power generation of the two photovoltaic projects is 2.8058 million kWh and aim to reduce carbon dioxide emissions by 3035.92 tons per year, equivalent to the reduction of 1241.4 acres of forest emissions, and save about 998.78 tons of standard coal per year.

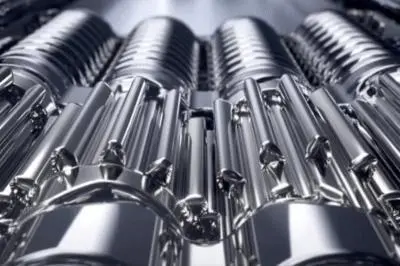

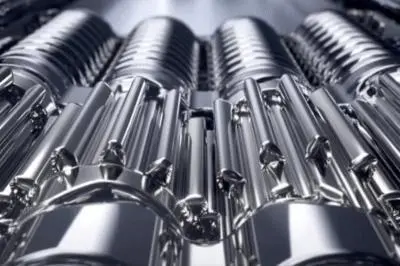

Milestone 2: Recycling and Reusing of Scrap Steel

Scrap steel is a renewable resource and the only alternative steelmaking raw material to iron ore. Utilization scrap steel saves more energy than primary ore development. Data shows that 1 ton of ordinary scrap steel equals 3-4 tons of iron ore and 1-1.5 tons of coke. It can also be infinitely recycled.

Compared to iron ore, the use of one ton of scrap steel can reduce carbon dioxide emissions by 1.6 tons, with a maximum reduction of 76% in wastewater, 72% in slag, and 86% in exhaust emissions. The "14th Five Year Plan for the Development of Circular Economy" shows that in 2020, the utilization of scrap steel will be about 260 million tons, replacing 62% grade iron concentrate by about 410 million tons. At the same time, it is clearly set that the utilization of scrap steel in China will reach 320 million tons by 2025.

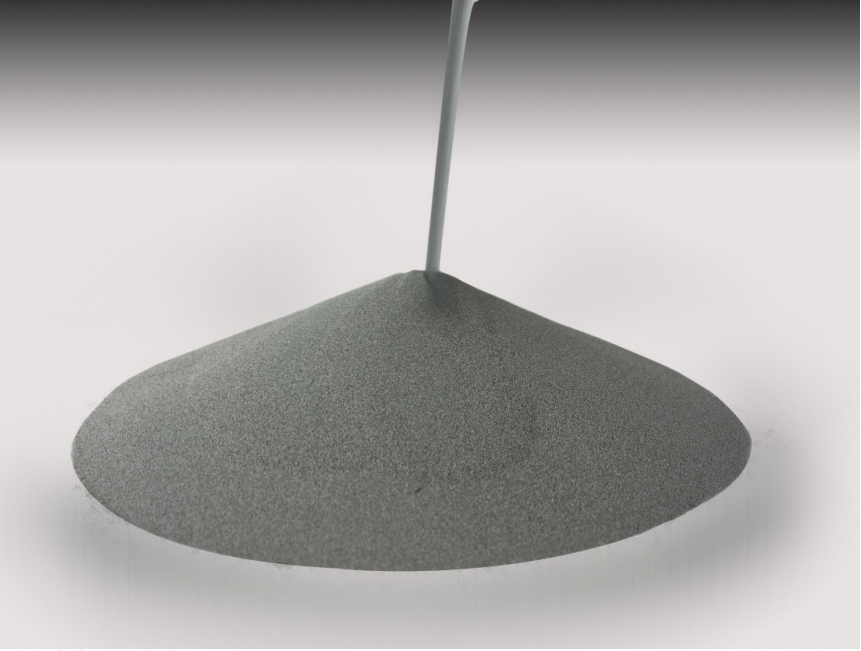

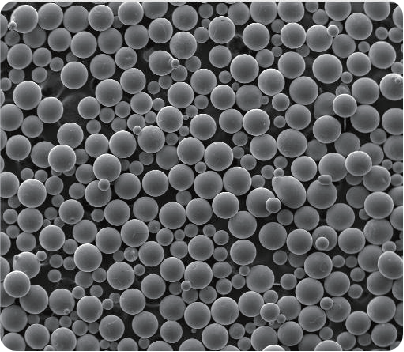

The company adheres to the circular economy principle and aims to reduce natural resource consumption and production waste. The recycled scrap steel has been reused for production. The grades of 316L, 304L, 17-4PH and high-strength steel used for folding screen phone hinges and nickel free stainless steel from scrap steel have been certified by authoritative international certification bodies with a recycled material content of >80%.The atomized alloy powder series products produced from scrap steel recycling have obtained two international authoritative certifications for recycled ingredients, with a recycled material content of>80%.The atomized alloy powder series can customize the recycling ratio according to customer needs.

Recognition from industry authorities proves the company’s ability to use recycled resources for high-quality products and the YUEAN's dedication to supporting the circular economy.

Reusing materials helps reduce dependence on non-renewable resources, reduce waste emissions, and handle the environmental waste. YUEAN Advanced Materials commits to energy improvement and emissions reduction with strategic investment in research and developing recycled materials for titanium alloy powder. A series of new products are on schedule for release.

Reusing materials helps reduce dependence on non-renewable resources, reduce waste emissions, and handle the environmental waste. YUEAN Advanced Materials commits to energy improvement and emissions reduction with strategic investment in research and developing recycled materials for titanium alloy powder. A series of new products are on schedule for release.

YUEAN Advanced Materials will continue to play a role in implementing the national "carbon neutrality" goal and contribute to the country's sustainable development.